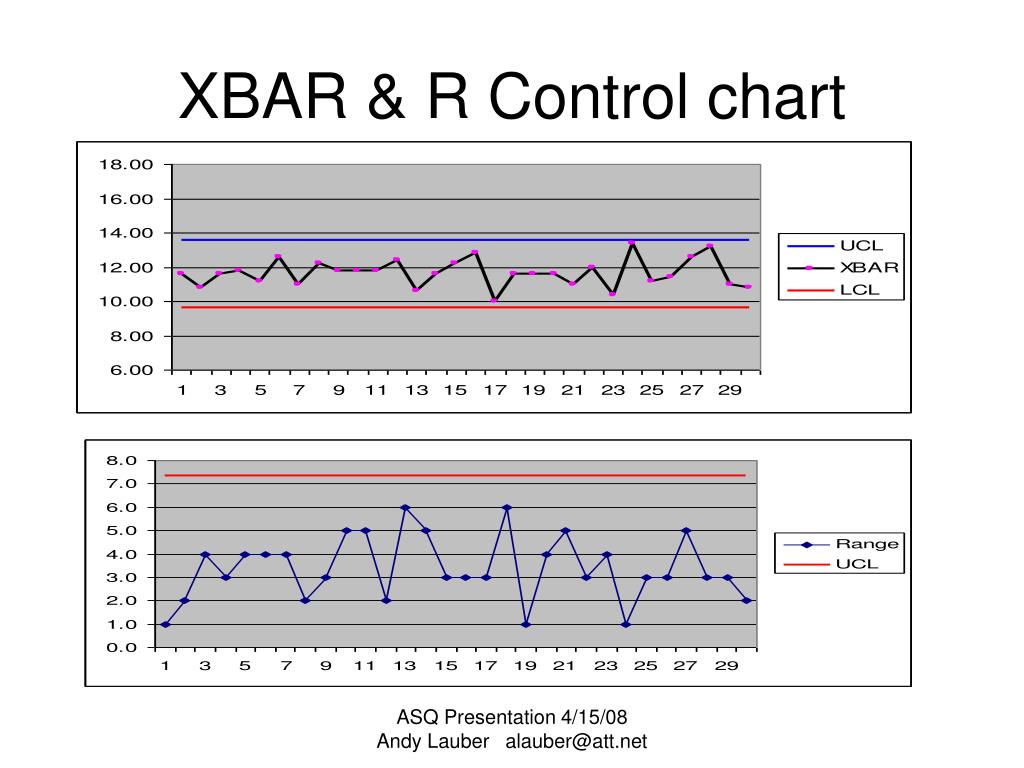

Each point in the range chart corresponds to the point in the X-Bar chart above it. The range chart shows how much the sub group varies.

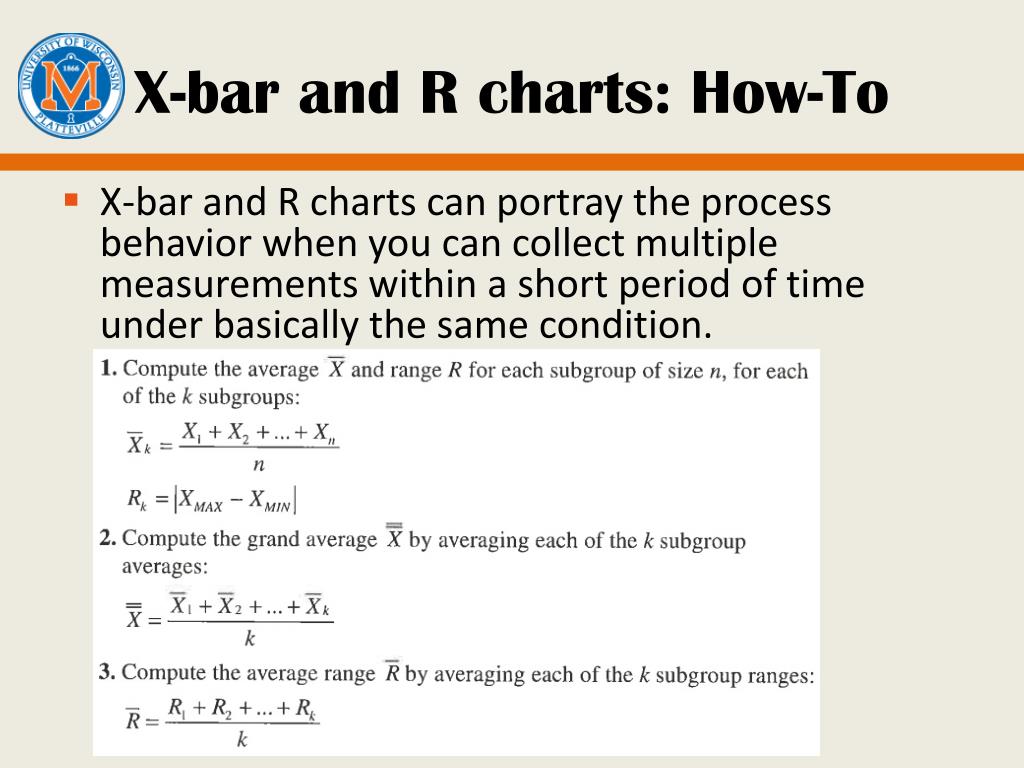

In Figure 3 the X-Bar chart is included in the top part of the chart and the range chart in the bottom. The X-Bar and R (range) chart can be displayed in two ways. The center line in this chart is the average of the averages or X Double Bar. The disadvantage is over smoothing the data can lead to misreading or misrepresentation of the information.Īn X-Bar chart will usually include limits calculated to show control, not specification. Smoothing the data can show trends that are hard to see in the raw data. Using an X-Bar chart is beneficial when the data is noisy or has a lot of variance. You can see this between the X-Chart (Fig 1) above and the X-Bar chart below (Fig 2). The more points in the sub group, the smoother the chart becomes. This is also called statistical smoothing. The X-Bar chart averages multiple data points together into a sub group then plots the average or mean of the sub group. While it doesn’t tell you if the measurement is within spec. Six-Sigma limits when applied to process measurement data usually are calculated +/- three-sigma from the running average. Control limits can be set using actual or absolute limits the measured item must stay within or can be based on a standard such as Six-Sigma.Īn example of actual or absolute limits can be that the material thickness must be between. These charts often include the average of the data points (X-Bar) and control limits. The X-Chart is a plot of every data point without any averaging.

0 kommentar(er)

0 kommentar(er)